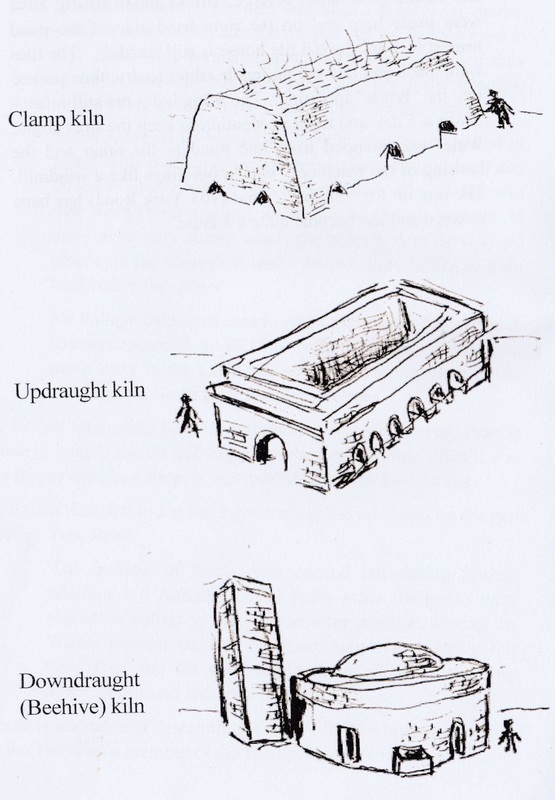

CLAMPS

The oldest method of firing is by clamp. This process was used at Francis Pulleyn's brickyard. A clamp is a temporary construction

of unfired bricks which is usually dismantled after each firing and is erected again near to the clay that is being used. Clamps had level

floors of burnt brick. Channels were made in the floor and filled with coke or other fuel. 3 or 4 layers of unfired bricks were placed on edge and then another layer of fuel was added. Then unfired bricks were packed closely together to a height of 14 or 15 feet - usually tilting slightly inwards to prevent falling. Most clamp bricks had a little coke added to the clay. This helped a good temperature to be reached. The blue -black tinges that can be seen on early Haxby bricks will most likely have been caused by the coke. The clamps usually contained 30,000 - 150,000 bricks taking 2 to 3 weeks to burn out.

The oldest method of firing is by clamp. This process was used at Francis Pulleyn's brickyard. A clamp is a temporary construction

of unfired bricks which is usually dismantled after each firing and is erected again near to the clay that is being used. Clamps had level

floors of burnt brick. Channels were made in the floor and filled with coke or other fuel. 3 or 4 layers of unfired bricks were placed on edge and then another layer of fuel was added. Then unfired bricks were packed closely together to a height of 14 or 15 feet - usually tilting slightly inwards to prevent falling. Most clamp bricks had a little coke added to the clay. This helped a good temperature to be reached. The blue -black tinges that can be seen on early Haxby bricks will most likely have been caused by the coke. The clamps usually contained 30,000 - 150,000 bricks taking 2 to 3 weeks to burn out.

UPDRAUGHT KILNS

These were also known as Scotch kilns. They were permanent structures. They were built of burnt brick. Flues ran under the perforated floor. The unfired bricks were stacked on the floor with small gaps between them to allow the heat to circulate. The

open top of the kiln was covered with old burnt bricks and turf or very wet clay to conserve the heat. The kilns had to be stoked

regularly day and night for 3 or 4 days. Quite often flames could be seen rising from the top of the kilns. Because of this, these kinds of kilns could no longer be used in 1939 when strict black-out regulations came into force during the 2nd World War.

Photographs below of the kilns used at the Driffield's brickyard suggest that this kind of kiln was used there. These photographs were taken by the Haxby Women's Institute around 1960. The right hand image shows the firing holes and the second one on the right the door way for the kiln.

These were also known as Scotch kilns. They were permanent structures. They were built of burnt brick. Flues ran under the perforated floor. The unfired bricks were stacked on the floor with small gaps between them to allow the heat to circulate. The

open top of the kiln was covered with old burnt bricks and turf or very wet clay to conserve the heat. The kilns had to be stoked

regularly day and night for 3 or 4 days. Quite often flames could be seen rising from the top of the kilns. Because of this, these kinds of kilns could no longer be used in 1939 when strict black-out regulations came into force during the 2nd World War.

Photographs below of the kilns used at the Driffield's brickyard suggest that this kind of kiln was used there. These photographs were taken by the Haxby Women's Institute around 1960. The right hand image shows the firing holes and the second one on the right the door way for the kiln.

DOWN DRAUGHT KILNS

The downdraught, circular or beehive kiln was more efficient than the other two types of kiln. It had a domed roof and a perforated

floor. A flue ran under the floor leading to a chimney stack, There were about 8 fireholes and inside these were firebricks. These kilns

held about 12,000 unfired bricks. Coal was lit inside the firehole grates and hot gasses were directed upwards and then downwards from the inside of the dome by the draught from the chimney. The kiln took 14 days to operate and several more days for loading, heating to full temperature, cooling down, and unloading.

The base of one of these kinds of kilns has been found on the site of the brick works in New Earswick and another one at the site of the Hob Moor brick works. The image on the left below shows the base of a downdraught (beehive) kiln recently discovered at the site of the New Earswick brick works, (in the nature reserve by lock cottage). The photograph is by Will Durrant, Lock Cottage, New Earswick. The image on the left shows three beehive kilns at Porth Wen on Anglesey, the photograph is by D Sallery.

The downdraught, circular or beehive kiln was more efficient than the other two types of kiln. It had a domed roof and a perforated

floor. A flue ran under the floor leading to a chimney stack, There were about 8 fireholes and inside these were firebricks. These kilns

held about 12,000 unfired bricks. Coal was lit inside the firehole grates and hot gasses were directed upwards and then downwards from the inside of the dome by the draught from the chimney. The kiln took 14 days to operate and several more days for loading, heating to full temperature, cooling down, and unloading.

The base of one of these kinds of kilns has been found on the site of the brick works in New Earswick and another one at the site of the Hob Moor brick works. The image on the left below shows the base of a downdraught (beehive) kiln recently discovered at the site of the New Earswick brick works, (in the nature reserve by lock cottage). The photograph is by Will Durrant, Lock Cottage, New Earswick. The image on the left shows three beehive kilns at Porth Wen on Anglesey, the photograph is by D Sallery.

The photograph below belonged to Brian Mann's father. It is thought to show Haxby men digging a pond for the extraction of clay. The date may be around 1920.